Solutions for carton marking and individualization

Marking cardboard boxes in many ways

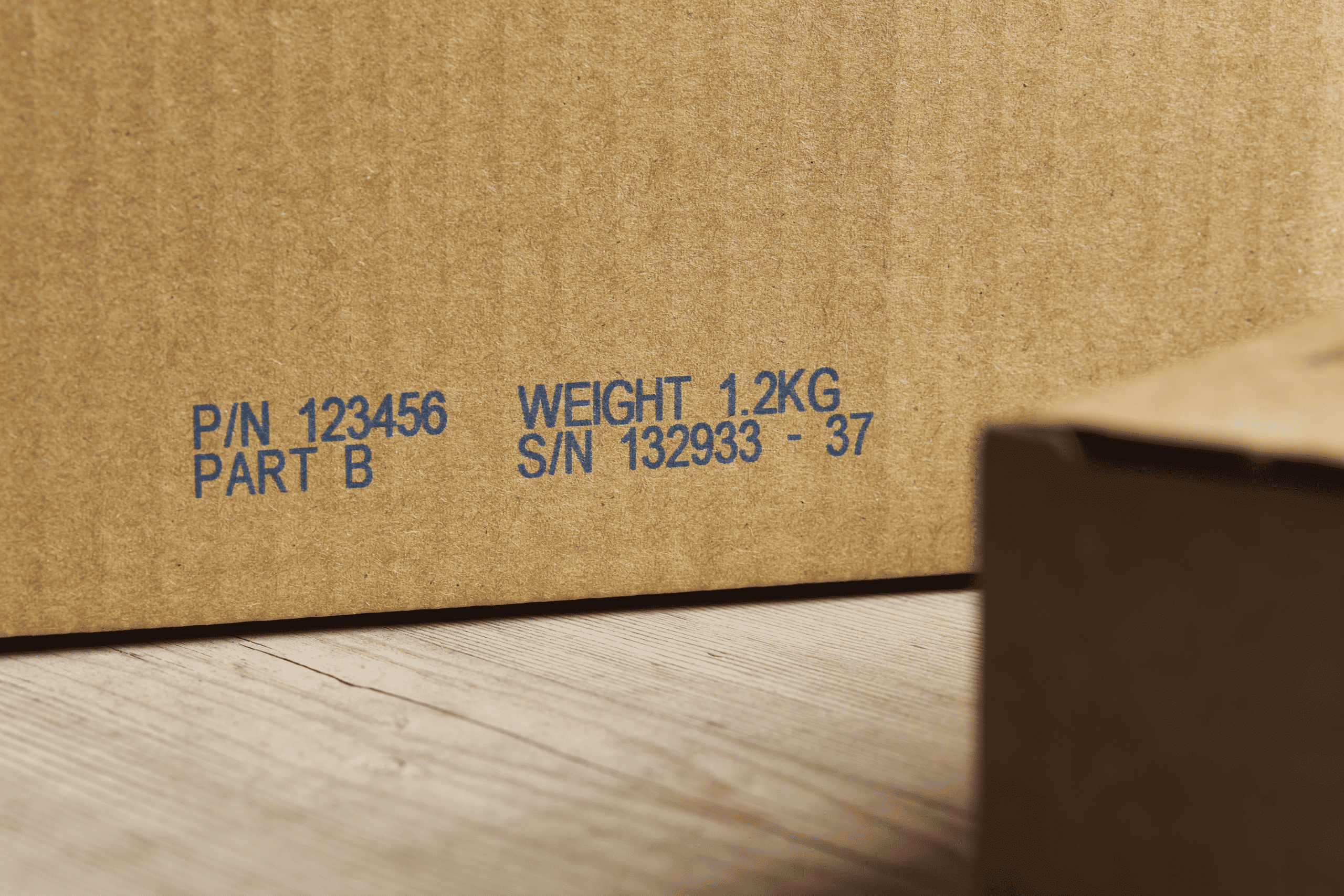

Whether as primary or secondary packaging, cardboard is used to safely package all kinds of products. Without these packaging materials, many of our everyday products would not be distributable or storable. They must be labeled accordingly with a wide range of information, whether for shipping, tracking or manufacturing. Cardboard or paperboard packaging can be printed, labeled or laser marked. Batch numbers, codes and information such as the best-before date must be printed legibly and permanently. This is because products can have a long shelf life and be stored under a wide variety of conditions. These requirements are met perfectly with high-resolution inkjet printers.

Which method is suitable for marking cardboard?

Larger layouts are often present when marking cardboard, so print heights of 25, 50 or even 100 mm are necessary. Barcodes must be applied in high quality so that they are easily legible on most brown cardboard. High-resolution inkjet marking systems are particularly well suited for direct and large-area marking of cartons. They offer razor-sharp image quality, low printing costs, maximum flexibility in print design and maximum barcode readability even on highly fibrous cardboard. The systems replace any existing label solution as well as pre-printed cardboard.