Marking with Continuous Inkjet (CIJ)

Basic functionality of CIJ

Continuous Inkjet (CIJ) technology involves the continuous release of tiny droplets of ink from a nozzle, which are then selectively charged and directed towards the substrate to form the desired image or pattern. The process starts with the ink being pressurized and forced through a small nozzle, creating a continuous stream of droplets. Next, an electric charge is applied to the droplets by electrodes near the nozzle, causing some droplets to be deflected towards the substrate and others to be directed towards a waste container. The printhead moves across the substrate, repeating the process to create the desired image. The charged droplets are then deposited onto the substrate to form the image, and the uncharged droplets are collected as waste.

Advantages of Continuous Inkjet

Continuous Inkjet is particularly suitable for marking large quantities due to the low variable printing costs.

- fast print speed up to 588 m/min

- large distance of up to 5.0 cm from printhead to product

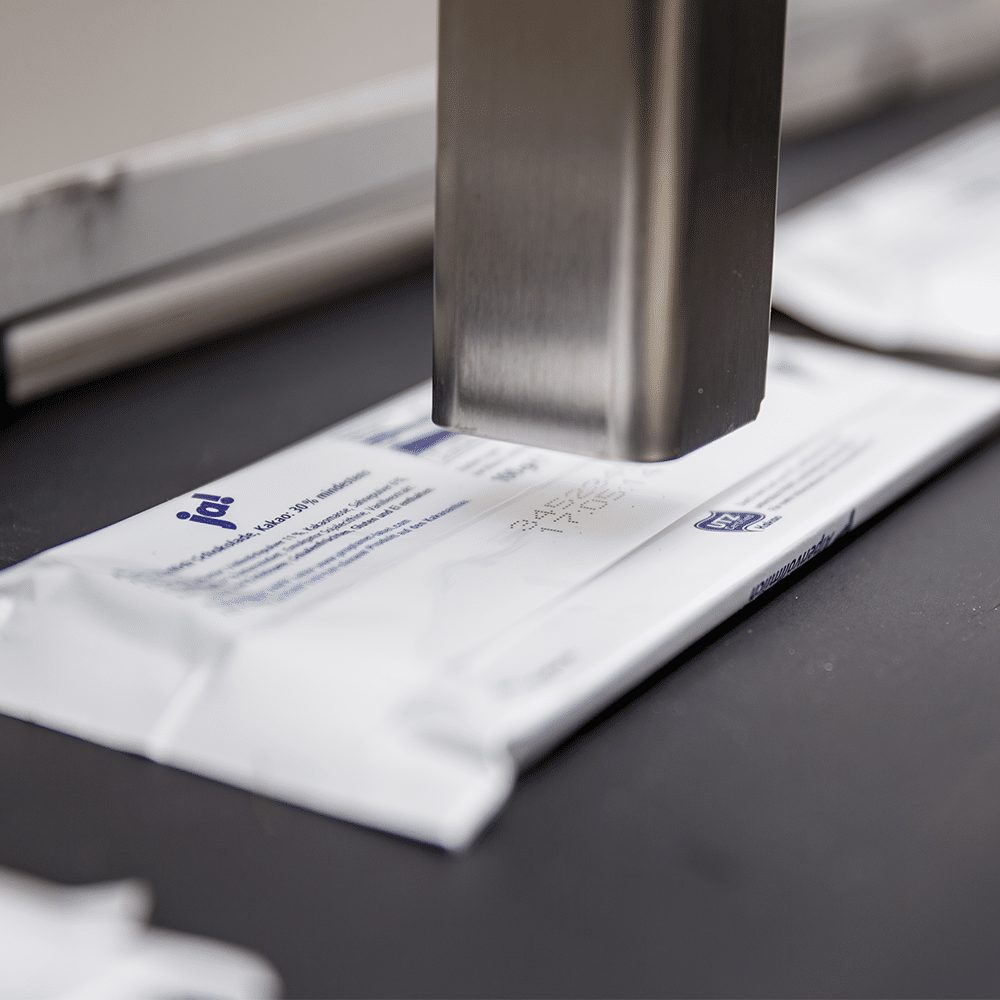

What do Continuous Inkjet printers print on?

- printing on round, uneven and smooth surfaces thanks to non-contact printing technology

- industry-specific solutions with adhesion on almost all surfaces thanks to the large ink portfolio

- high print quality of logos, barcodes, 2D codes and texts