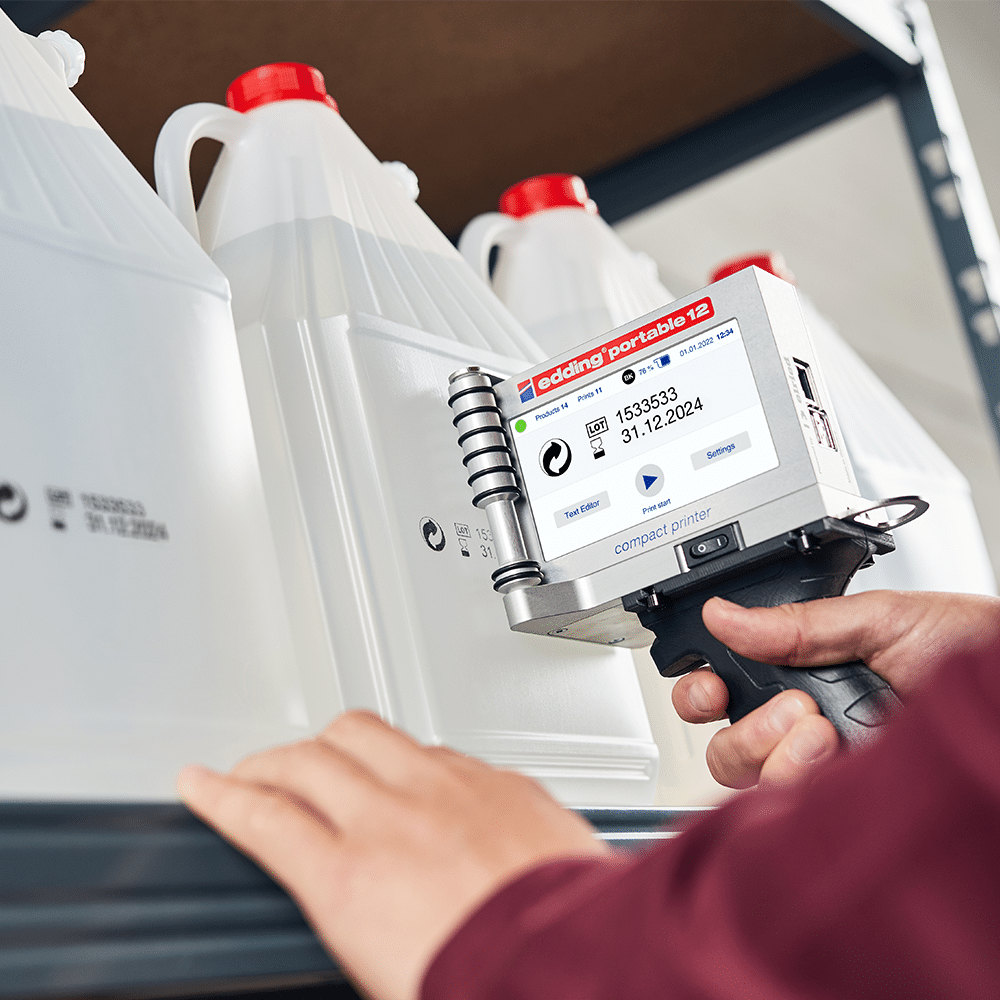

Marking with Thermal Inkjet (TIJ) / "Cartridge systems"

Basic functionality of TIJ

Thermal Inkjet (TIJ) technology uses heat to create and eject droplets of ink from a printhead onto a substrate. The process starts with ink being held in a reservoir within the printhead. When a print command is received, a heating element within the printhead rapidly heats the ink, causing a small amount of ink to vaporize and form a bubble. The pressure created by the expanding bubble forces a droplet of ink out of the nozzle and onto the substrate. This process is repeated rapidly and in a precise pattern to create the desired image or text. The heating element then cools, and the pressure returns to normal, allowing the ink in the reservoir to refill the chamber and prepare for the next droplet to be ejected.

Advantages of Thermal Inkjet

Thermal Inkjet is a highly innovative technology that can be used in almost all marking requirements.

- very high reliability, no downtime

- easy to use, requires no training

- extensive integration possibilities – Industry 4.0

What do thermal inkjet printers print on?

- printing on almost all surfaces: plastics, metal, glass, cardboard, wood etc.

- ink type and color can be changed with one click

- maximum print quality of logos, barcodes, 2D codes & texts