Process printing

Various options of printing to identify and mark products.

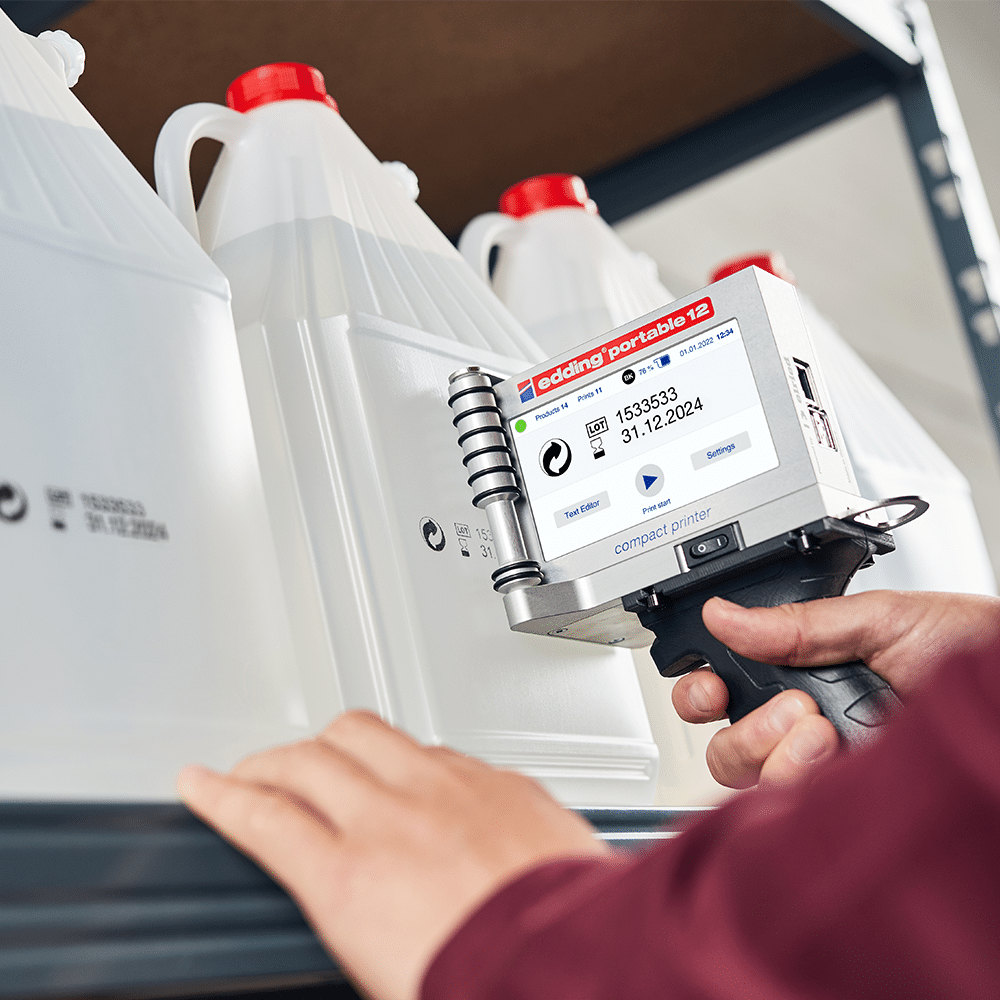

Thermal Inkjet (TIJ)

Thermal Inkjet (TIJ) technology uses heat to create and eject droplets of ink from a printhead onto a substrate. The process starts with ink being held in a reservoir within the printhead. ...

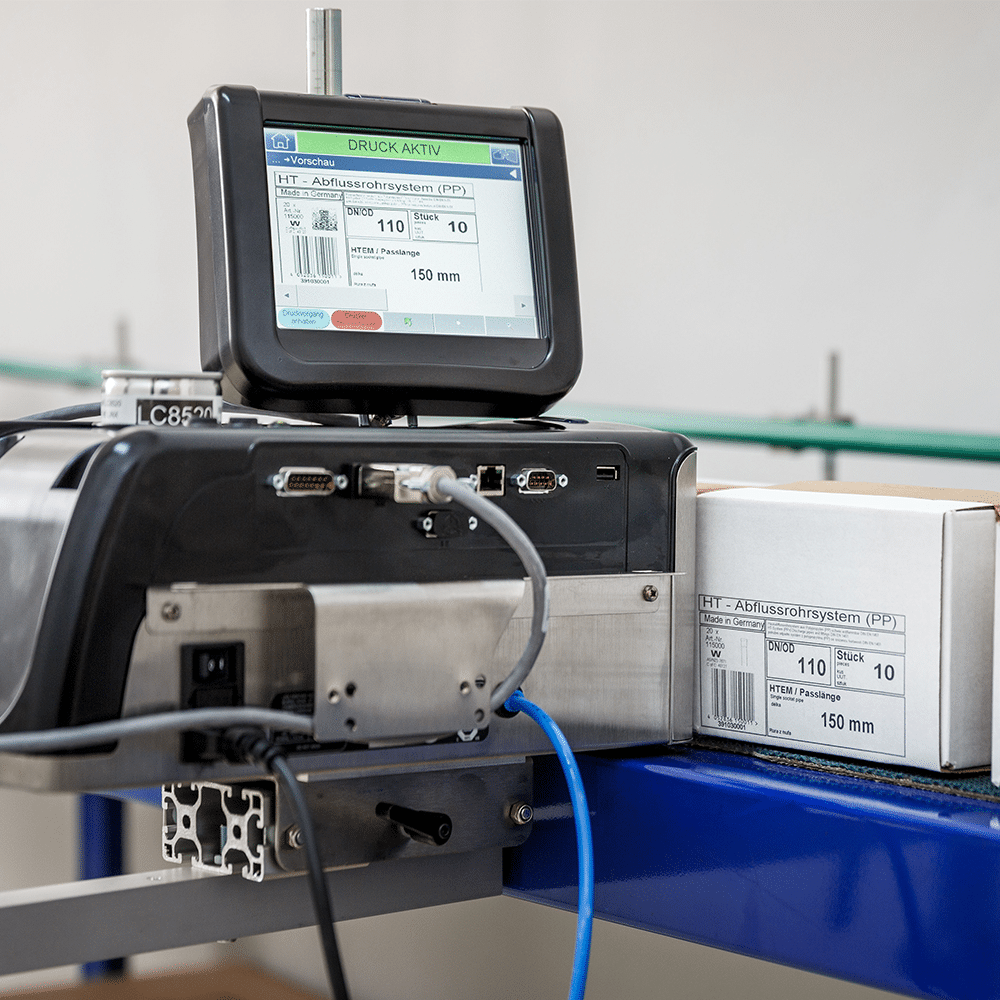

Continuous Inkjet (CIJ)

Continuous Inkjet (CIJ) technology involves the continuous release of tiny droplets of ink from a nozzle, which are then selectively charged and directed towards ...

Piezo Inkjet

Piezo Inkjet technology uses mechanical pressure to create an ink droplet. In piezo inkjet, the ink is located in a chamber in the print head. When a print ...

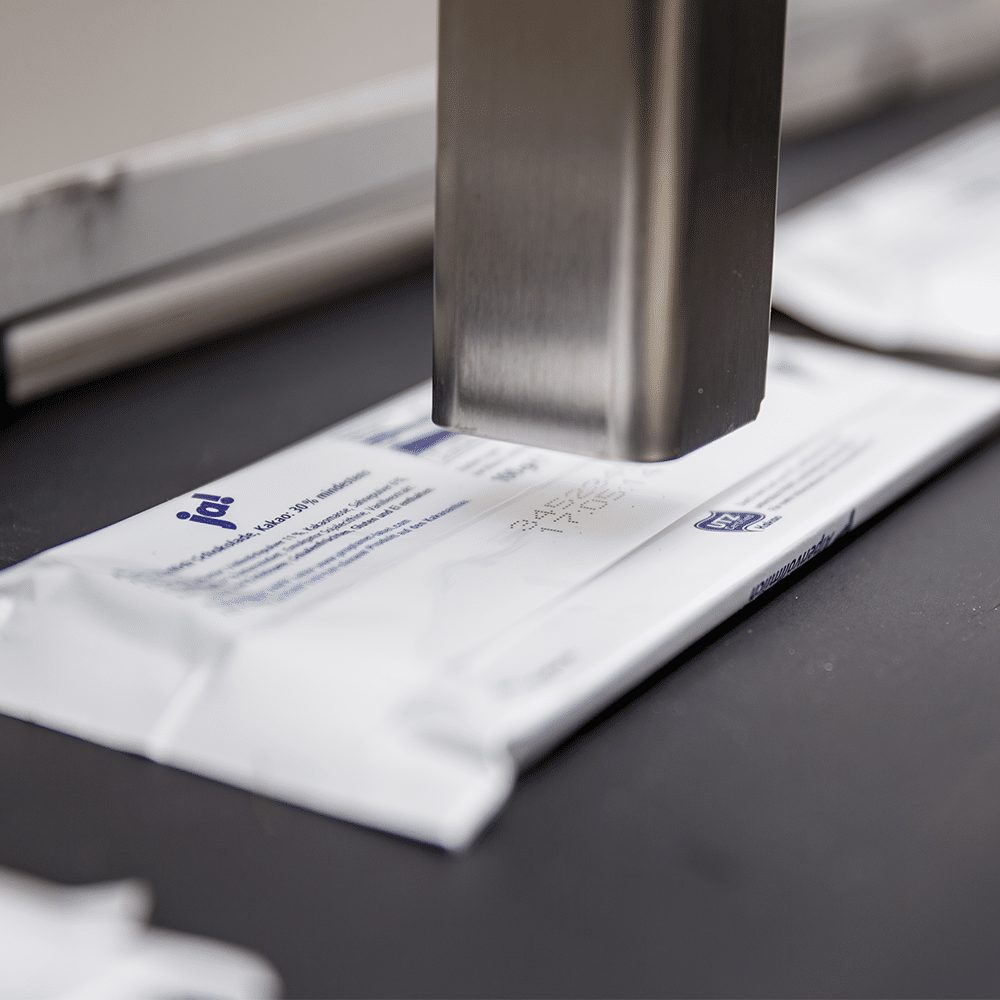

Thermal Transfer (TTO)

Thermal Transfer Overprinting (TTO) is a printing technique that can produce high-quality bar codes, text and images on a variety of materials including ...

Laser marking

Laser coding technology is a method of printing information, such as barcodes or text, onto a substrate using a laser beam. The process starts with ...

Interval- / pad printing

In interval or pad printing, a cliché is stamped directly onto the product. The cliché can be static or replaceable with ribbed rubber ...

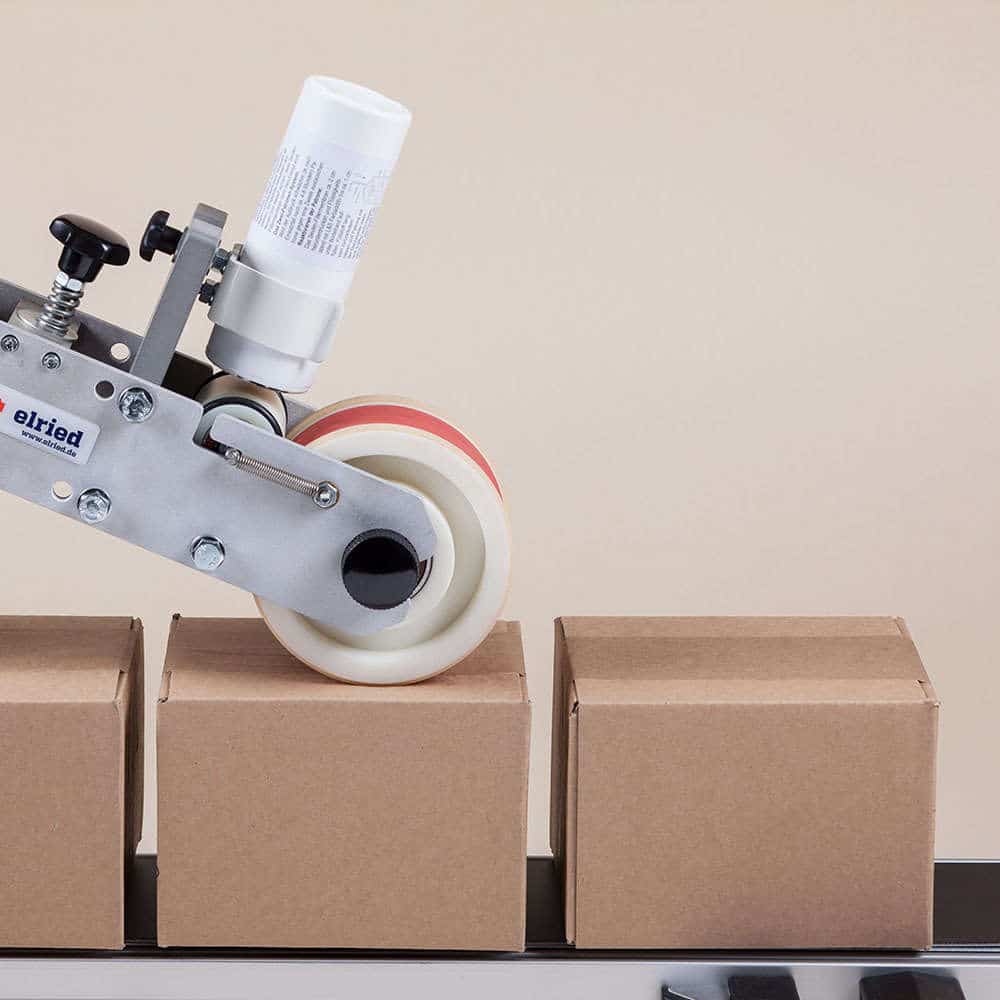

Coding units

In coders or also coding units, the text to be printed is on a printing drum. Usually interchangeable, in that the individual letters sit on ribbed rubbers. The coder ...

Spray marking

In spray marking, ink is sprayed onto the product at high pressure through a fine nozzle of the can. By manual pressure on the spray head, the valve is opened and ...

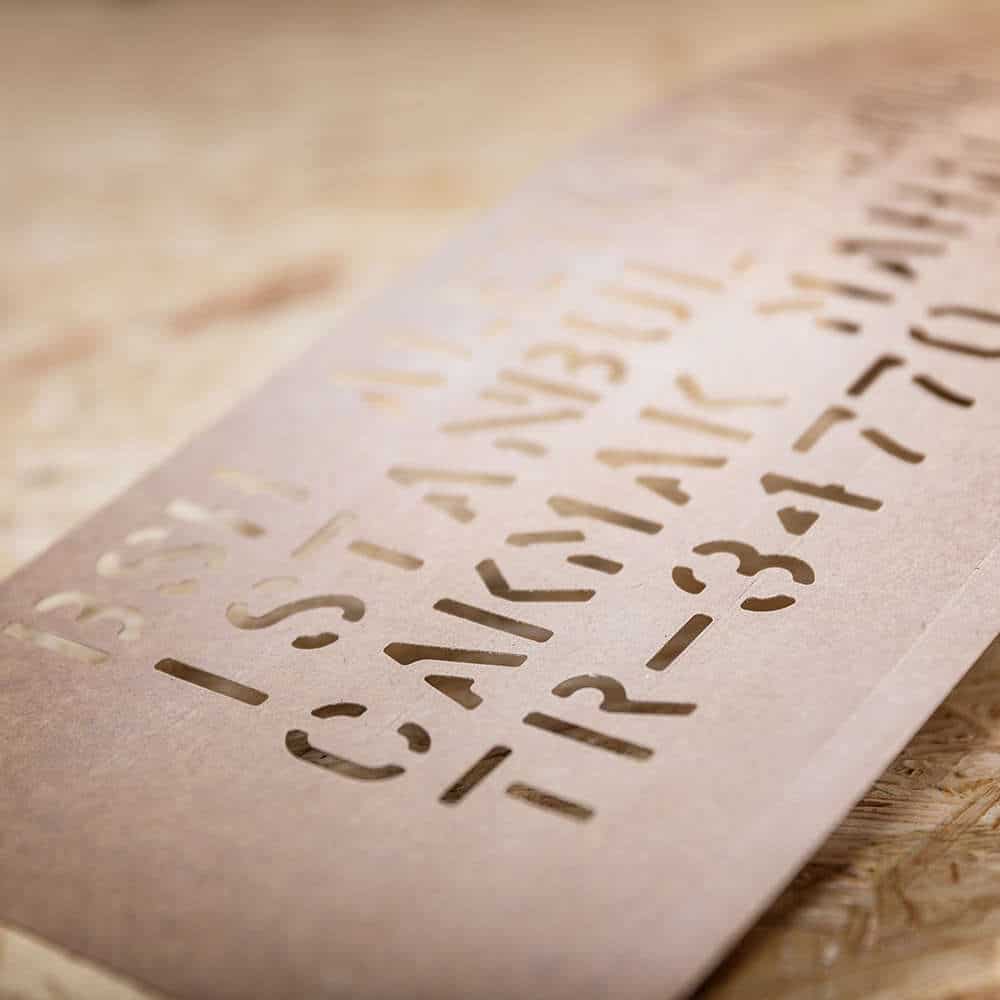

Stencil marking

Here, the marking is carried out with the aid of a stencil. The stencil is either sprayed with marking ink so that the content to be transferred is transferred to ...

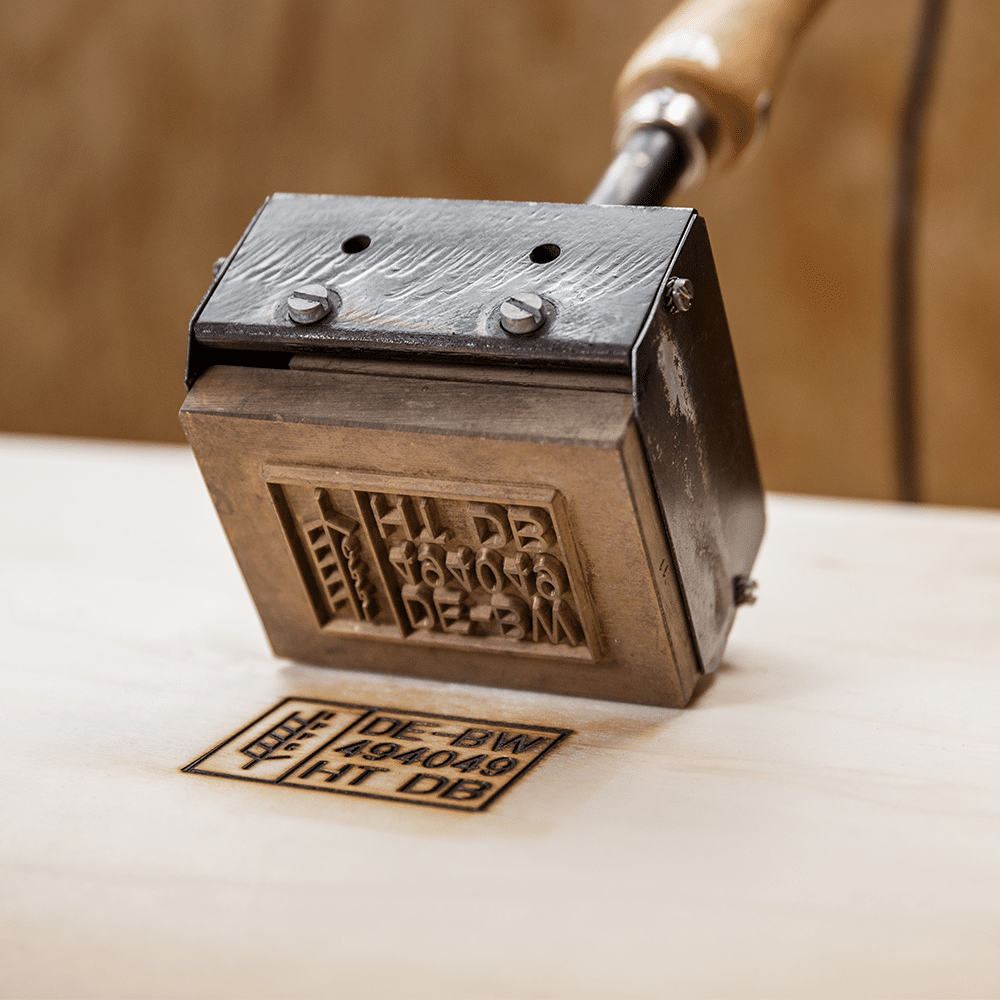

Stamp

Stamps are a classic, manual marking solution. Here, you have to print the stamp by hand on the surface to be marked. Therefore, this method is slower and ...