Our solutions for marking products with information of any kind

Readable, identifiable, traceable

Depending on the type of product, industry or country, there are as different as numerous regulations and laws for product labeling. The required contents can be: Best before date (BBD), batch numbers, bar codes, data matrix codes, production data or ingredients. Consumers are hereby protected and informed. Product coding contributes to plagiarism protection and complete traceability and enables manufacturers to easily control quality. Two methods can be used for product labeling. In direct product marking, the marking is applied directly to the products or their packaging using inkjet systems or lasers. In indirect product labeling, labels are printed and then affixed to the products or packaging.

What high-end labeling systems must achieve

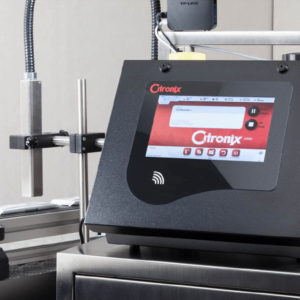

For fast and cost-efficient production, product labeling is ideally integrated into the production or packaging process. Systems for product marking should therefore be suitable for serial production. This means that, on the one hand, they have to withstand a wide variety of production environments (extreme temperatures, dust, humidity) and ensure the high cycle rate of production processes. On the other hand, their technology must be suitable for marking many surfaces, even those that are difficult to print on. From non-absorbent materials such as metal or plastic, to absorbent and porous materials such as wood, paper or cardboard, to smooth, round or uneven surfaces. For this reason, marking devices such as the edding inkjet systems are extremely robust, reliable and extremely fast to operate. An efficient technology for marking almost all surfaces!