Our solutions for defect marking

Check print and marking quality

In most cases, defect marking must be automatically followed by a pass/fail inspection.

or bad marking can be applied. Particularly high process reliability is required for this critical step. And especially in the case of bad part marking, which is often triggered infrequently, the system must also be able to withstand long downtimes without drying out.

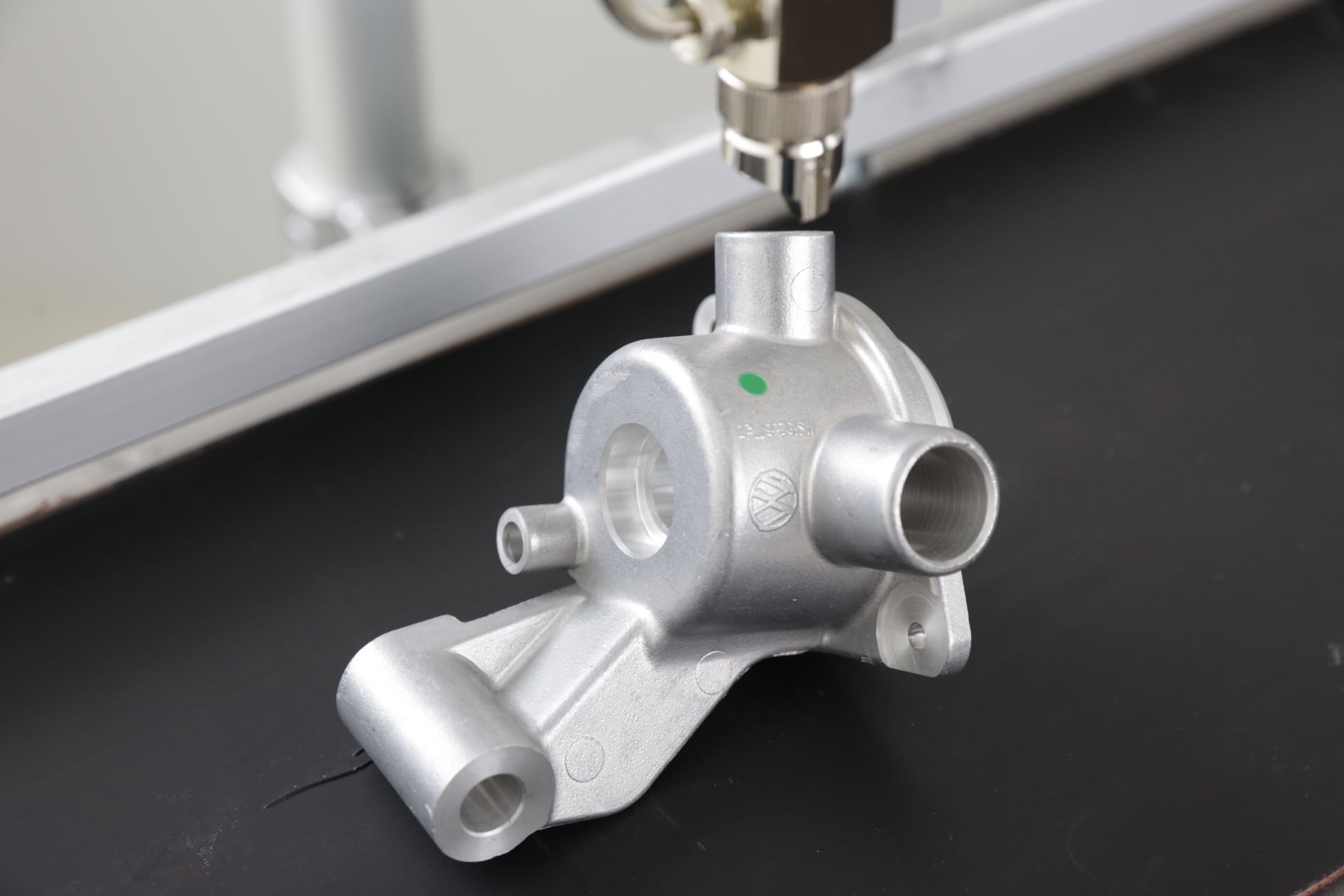

Special equipment such as the Sprayjets and Sprinter products can be used to apply defect or good markings in a process-safe manner, mostly in the form of a colored dot.

Highly efficient in defect marking and quality assurance: Sprayjet and Sprinter

The Sprayjet is a highly efficient system, especially for defect marking and quality assurance. The system sprays a color dot or line onto the passing material. Since almost any ink can be used, ink application is possible regardless of the material. The marking is triggered by a solenoid valve (24 volt signal) or completely pneumatically (hazardous area). This ensures a very high level of functional reliability. The Sprayjet is particularly suitable for users who are looking for a reliable and cost-effective system for their quality assurance.

The Sprinter systems are also designed for maximum reliability. In contrast to the sprayjet, a stamping process is used here. This allows significantly smaller and more precise markings. Through the stamp can be applied not only test points, but also any other shape or sequence of characters. Triggering is also pneumatic, so the system can also be used in hazardous areas.