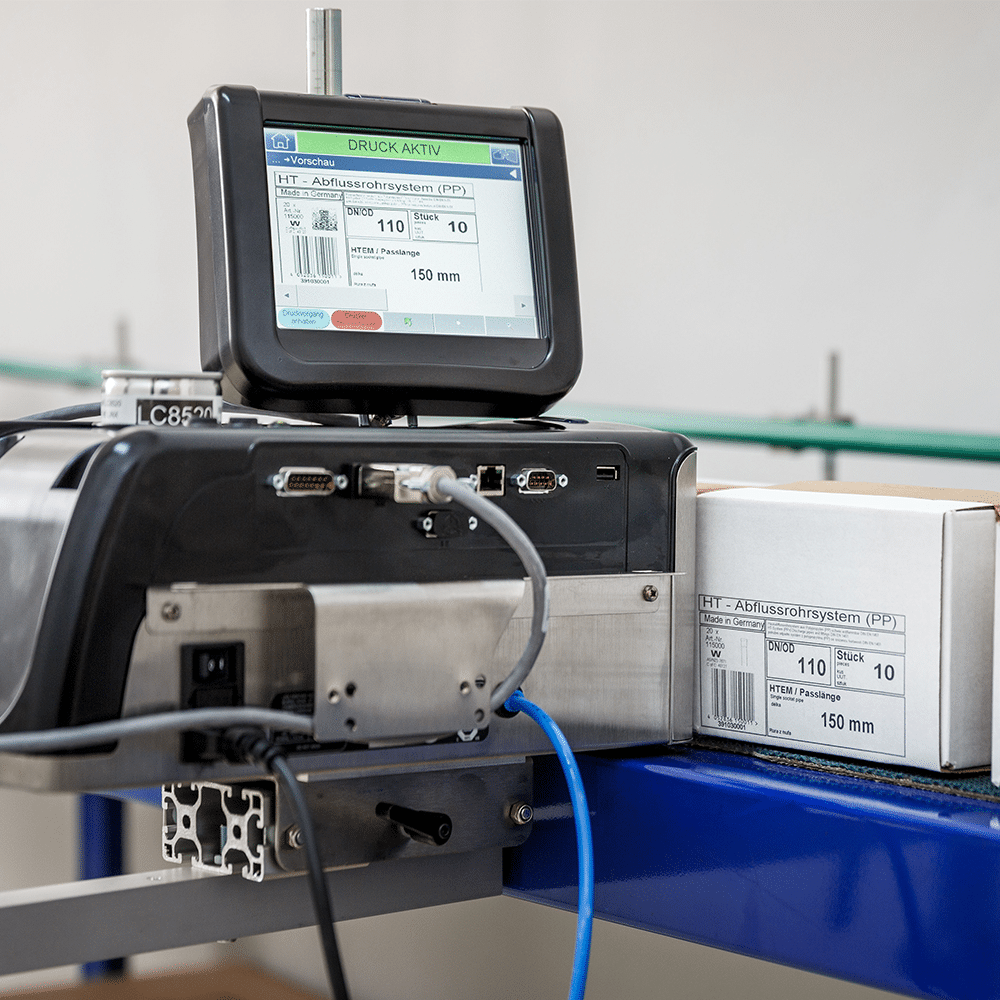

Marking with Piezo Inkjet systems

Basic functionality of Piezo Inkjet systems

Piezo Inkjet technology uses mechanical pressure to create an ink droplet. In piezo inkjet, the ink is located in a chamber in the print head. When a print command is received, the piezo element in the printhead deforms in response to an electrical charge, creating a pressure in the ink chamber. By generating pressure via volume change, an ink droplet emerges from the nozzle. Once the electrical charge is reversed, the piezoelectric element returns to its original shape and the pressure returns to normal, replenishing the ink in the chamber and preparing to eject the next drop. This process is repeated quickly and in a precise pattern to produce the desired image or text. Because the ink is not heated during the process, this technology is often used with more sensitive or heat-sensitive inks, such as ultraviolet (UV) curing inks.

Advantages of Piezo Inkjet

- allows very high print heights per head, therefore suitable for full-area marking

- works mostly with water- or oil-based inks, therefore low emissions

- inks are usually very high-contrast and can therefore replace labels

What do Piezo Inkjet printers print on?

- print mainly on absorbent surfaces such as paper or cardboard (not coated).

- high print quality of logos, barcodes, 2D codes & texts

- printing mostly from the side, therefore classic use in the marking of cardboard boxes as secondary packaging