Our solutions for labeling the best-before date (BBD) and other mandatory information on food packaging

Diverse requirements

According to EU Regulation 1169/2001 LMIV, food and beverages must be labeled. The markings inform end consumers about the minimum shelf life, nutritional values, ingredients and origin of foodstuffs and, with batch labeling, ensure complete traceability. When using suitable printing systems, the high hygiene requirements in the food and beverage industry must be met on the one hand. Secondly, the materials used (ink, labels) should be free of pollutants and solvents or pose no health risks. The choice of the appropriate food labeling system also depends on the packaging material – perfect legibility of text and codes is achieved differently on an egg carton than on a canned food or glass and PET bottle.

Error-free marking, even at high cycle rates

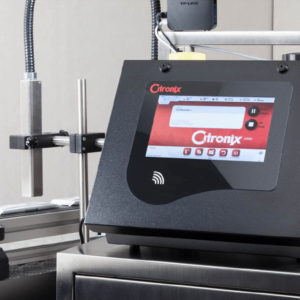

In view of the strict requirements for product labeling in the food industry, avoiding labeling errors is a top priority. To achieve this, the printing systems must be suitable above all for the high production speed or high cycle rates. Edding systems, for example, manage up to 270,000 prints per hour. They can also be used in dusty or humid production environments. Citronix continuous inkjet printers are fast, robust and hygienically safe. Since the LMIV (Food Information Regulation) also prescribes different font sizes for food labeling, inkjet systems are particularly suitable here. They also allow printing of low font heights for particularly small packages. Either a TTO or TIJ system is used for marking flexible film packaging; a laser system is often used for marking bottles.