Sustainability at Elried: Technology meets responsibility

Together for a more sustainable industry In industrial marking, many companies face the challenge of using solutions

The coding requirements for the wood industry are diverse and constantly increasing. In addition to the legally required CE and IPPC marking, retailers increasingly require information on origin as well as data on the traceability of goods.

Wood marking places a number of demands on the printing system.

The marking system must be fast and flexible to provide accurate print images for woods of different thicknesses

In addition, the printing system must be robust and function reliably under the most difficult conditions – dust exposure, temperature changes and vibrations.

What is needed is a solution that provides high-quality, highly visible as well as durable printing, often in the harshest production environments.

Basically, there are 6 different marking options for the requirements of marking in the wood sector. Due to the high fire risk of the branding irons and lasers, they are only suitable for the wood industry to a limited extent. Manual marking methods such as stamping or stenciling are very inflexible and labor-intensive.

Some manufacturers have automated their production lines with drop-on-demand printing systems. However, the print quality is far inferior to other technologies.

Edding compact printers offer the wood industry a very good price/performance ratio. The edding compact printers are based on clean thermal inkjet technology and are maintenance-free. There are no costly maintenance contracts and virtually no downtime.

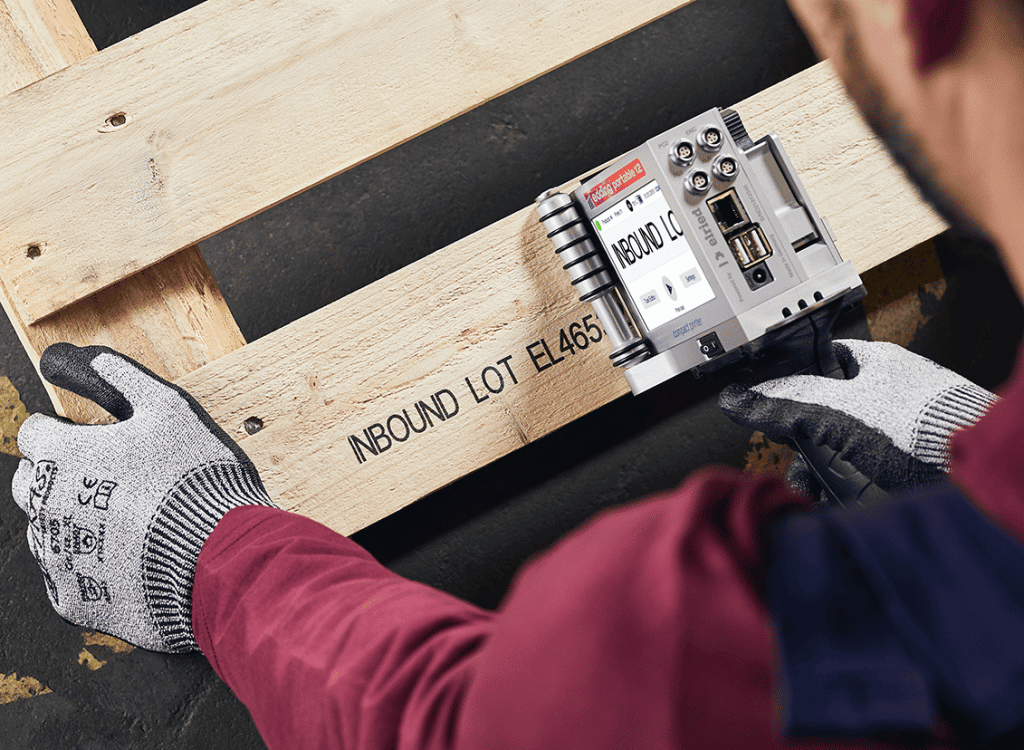

The edding in-line compact printer has numerous connection options and can be easily integrated into any production line. The edding portable offers even more versatility when marking is required outside the production line, with consistently high quality and reliable results. The design of the devices withstands the challenges of even the toughest production environments.

Together for a more sustainable industry In industrial marking, many companies face the challenge of using solutions

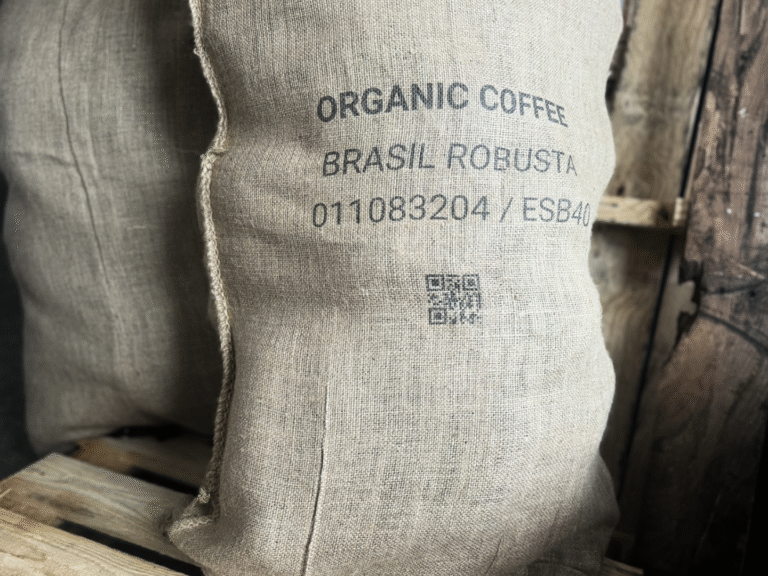

Transparency and quality: Printing jute bags in coffee production From cultivation and roasting to the finished product,

The beer industry is changing. Craft beer and speciality varieties in particular are becoming increasingly important worldwide.

Take your production processes to a new level with the edding in-line Pro! The edding in-line Pro

7 innovative applications for the edding portable 50 The edding portable 50 is a high-resolution inkjet printer

A remarkable success story shows how innovation and collaboration can take businesses to the next level. Elried

By loading the product search, you accept Doofinder's privacy policy.

Learn more